At COMPUTEX, major electronics firms such as Foxconn, Pegatron, and Wistron are showcasing cutting-edge automation technologies utilizing generative AI in manufacturing and IoT. These giants are leveraging NVIDIA’s solutions to enhance efficiency and safety in the smart factories of the future.

Building Autonomous Factories

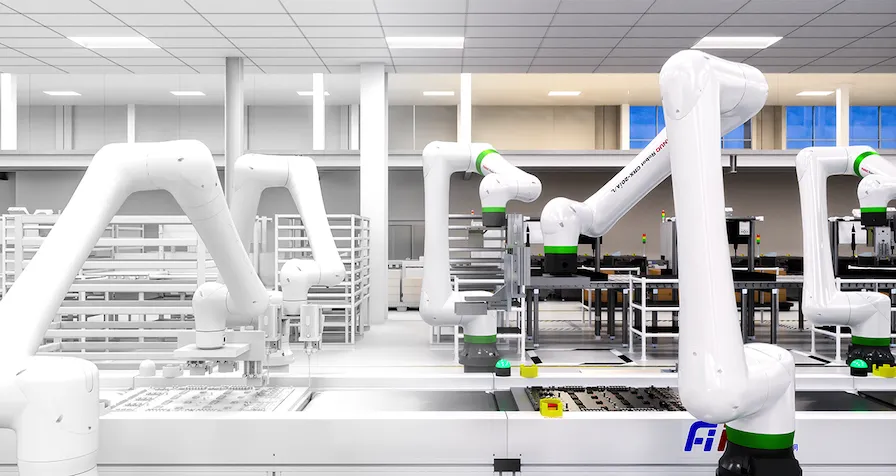

Faced with increasing production challenges, manufacturers are transforming factories into autonomous systems, underpinned by generative AI and digital twins. Large language models (LLMs) drive AI agents that can communicate and assist on warehouse floors, boosting productivity and safety. Digital twins allow manufacturers to simulate and develop factories and AI-driven automation before real-world deployment.

Foxconn and its subsidiary Ingrasys use NVIDIA Omniverse and Metropolis to create digital twins for their factories, optimizing efficiency and improving worker safety. At COMPUTEX, Foxconn demonstrated how digital twins can plan camera placements in factories to optimize data capture.

Bringing Generative AI to Factories

Generative AI is revolutionizing productivity across various industries. McKinsey forecasts that generative AI could add up to $290 billion in value to the advanced manufacturing sector and contribute $4.4 trillion annually to the global economy.

In March, at GTC, NVIDIA unveiled NVIDIA NIM, a set of microservices designed to accelerate generative AI deployment in enterprises. Supporting a wide range of AI models, NVIDIA NIM ensures seamless and scalable AI inference, both on-premises and in the cloud, utilizing industry-standard APIs.

Billions of IoT devices globally can tap into Metropolis and NVIDIA NIM to enhance AI perception capabilities.

Enhancing Manufacturing with NVIDIA NIM

Linker Vision, an AI vision insights specialist, is adopting NVIDIA NIM to deploy AI agents capable of responding to natural language queries in factories. The Taipei-based company uses NVIDIA Visual Insight Agent (VIA) for continuous video monitoring of factory floors, providing safety alerts such as when workers are not wearing hard hats.

Leading manufacturer Pegatron, with over 20 million square feet of factory space assembling more than 15 million products monthly and deploying over 3,500 robots, is utilizing Metropolis’ multi-camera tracking workflow to enhance worker safety and productivity on production lines.

Boosting Automated Visual Inspections

NVIDIA Metropolis is streamlining operations and reducing costs for Taiwan’s largest electronics manufacturers, who produce and inspect some of the world’s most complex and high-volume products. The Metropolis for Factories workflow offers advanced AI applications for sophisticated and accurate automated optical inspection (AOI).

TRI, Taiwan’s leading AOI equipment maker, has integrated the Metropolis for Factories workflow into its latest AOI systems and plans to use NVIDIA NIM to further optimize system performance.

Wistron is expanding its OneAI platform for visual inspection and AOI with Metropolis, deployed in over 10 factories globally. MediaTek is collaborating with NVIDIA to integrate TAO’s pretrained models into its AI development workflow for IoT device customers, simplifying software development for the next phase of growth in edge IoT.

Discover more about NVIDIA Metropolis for Factories, NVIDIA NIM, and the Metropolis multi-camera tracking workflow, which developers can use to build state-of-the-art real-time locating services and enhance worker safety in factory or warehouse operations.